February 13, 2020

Toyota Motor Corporation is known for quality and reliability in the automotive industry. Continuous improvement is one of the core principles of the organization.

Always looking for ways to improve and innovate its processes, Toyota wanted to make the new model development process more efficient and cost-effective. Engineers wanted more flexibility, easier collaboration, and the freedom to test new ideas without having to resort to expensive and time-consuming Rapid Prototyping (RP) whenever more data was required.

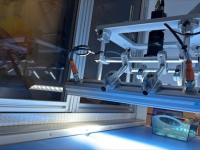

A number of possibilities were explored until they discovered Silverdraft, a full solutions company, who implemented the use of Extended Reality (XR) environments as part of Toyota’s new workflow. A key component of Toyota’s solution was Silverdraft’s DemonVR workstation equipped with two high performance NVIDIA Quadro RTX 6000 GPUs.

Silverdraft’s solution added a fully immersive VR environment to Toyota’s workflow, providing a photorealistic interactive visualization of design and assembly processes. “With the right solution, VR not only was creatively attractive; it made total business sense.

VR allowed us to improve New Model Development Cost by reducing travel and RP expenses; we achieved better lead times by identifying issues early on and starting trials earlier. There were quality and safety benefits as well, thanks to more training options, information digitization, and so on,” said Mark Kuzniarski, Digital Engineering Planning and Development Analyst for Toyota.

Fill out the information below to download the resource.

Latest News