June 22, 2015

This research brief examines adoption rates and challenges to increased adoption, along with the capabilities and characteristics design engineering teams find important when evaluating 3D printers.

Product design and development is increasingly a digital process. Simulations, virtual prototypes and digital twins help companies face the challenge of designing better, more complex products faster — but they only go so far. Design engineers need a physical prototype to validate form, fit and function, and to get approval on design changes. In the past, that meant expensive, time-consuming custom manufacturing that could be a bottleneck to product development. Now, 3D printing allows design engineers to quickly move between the digital and physical worlds so they can maintain the pace of innovation that is required by today’s tight product development deadlines.

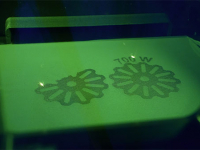

There are examples of 3D printing’s benefits in nearly every industry. The titans of the aerospace and automotive industries are using 3D printing technology for prototyping and end-use parts, following in the footsteps of smaller industry sectors like racing, jewelry making and prosthetics where 3D printing’s ease of customization is a key competitive advantage. Every day, more companies discover different ways that 3D printing can optimize their product design workflow.

This technology’s explosion in popularity among hobbyists, coupled with advances made in 3D printing applications and materials over the past 30-plus years, explains why the 3D printing market continues to see amazing growth. It grew at a compound annual growth rate (CAGR) of 35.2 percent to $4.1 billion in 2014, according to industry consultant Terry Wohlers. The future looks even brighter. IDTechEx estimates that the 3D printing market could reach $20 billion in revenues in the next decade. Still, some technological and cultural barriers remain. A recent study conducted among product and system design engineers by Peerless Research Group (PRG) on behalf of Desktop Engineering for Stratasys Ltd., confirms that 3D printing is primed for even greater acceptance once obstacles — such as cost, perceived lack of need and a greater understanding of the benefits — are addressed.

This research brief examines adoption rates and challenges to increased adoption, along with the capabilities and characteristics design engineering teams find important when evaluating 3D printers. It also shows that, as a means of broadening the scope of end users’ capabilities, outsourcing of 3D printing services is a viable option for many companies.

Fill out the information below to download the resource.

Latest News

Related Topics