Improve Powder Utilization by Investigating the Property Effects of Reusing AM Powders

Reduced powder costs up to 80% by reusing powder in the SLS process.

September 12, 2019

PROBLEM

High material costs are a major economic reason for continued limited application of additive manufacturing (AM) for batch production. Powders are expensive; nylon 12 powders, for example, cost between $75 and $100 per kilogram, while titanium is roughly twice that amount.

In a typical build, only 5-20% of the powder volume is fused into useful parts. The economic models must take into account the powder that is discarded, making the material in AM parts up to five times more expensive than the raw powder.

OBJECTIVE

The objective of this program was to provide a substantial reduction in material costs for orthopedic applications involved in AM part production by decreasing the amount of discarded powder.

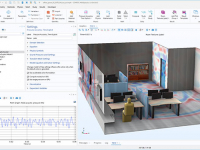

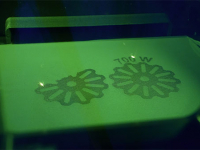

The materials considered were titanium (Ti-6Al-4V), two types of stainless steel (316L and 17-4 PH), and nylon 12. To quantify the changes resulting from the number of reuses in selective laser sintering (SLS), a powder bed fusion process, a total of eight reuse cycles was completed for each powder. Tensile testing, printed part densities, chemical analysis, and powder characterization were performed and analyzed.

Fill out the information below to download the resource.

Latest News