Getting Started with Office 3D Printing

What can you expect once your 3D printers are up and running? If you have chosen the right 3D printer for your needs, any operational challenges should be avoided.

June 2, 2020

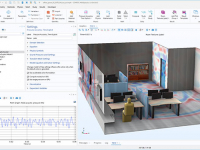

With its multiple benefits, 3D printing presents both an exciting and potentially overwhelming prospect. When you’re introducing in-house 3D printing, it can therefore be daunting to consider the workflow and process changes needed. A pragmatic approach is necessary, based on identifying the key time and cost-saving opportunities.

These include:

- Faster prototyping cycles

- Less design process interruption

- Reduced lead times when compared with outsourcing

- The ability to evaluate more design iterations, improving product quality

- Rapid ROI and cost savings

- The ability to customize tools and other end-use parts

3D printing technology

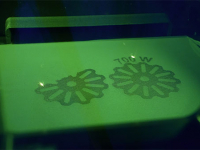

Fused filament fabrication (FFF) is the most widely adopted 3D printing technology in the world. The process involves material being extruded from a heated nozzle, and deposited on a build plate in thin layers, to form a printed object. The extruder moves horizontally to deposit material on the build plate, which moves vertically after each layer is completed.

FFF offers multiple advantages, including the broad availability of a range of materials. These are inexpensive and ideal for producing multiple applications, from prototypes to final product fabrication. FFF 3D printers can also be used for applications such as mold creation, tooling, and low-volume custom part fabrication.

Fill out the information below to download the resource.

Latest News