Whether you’re designing something as complex as a cooling channel for an automotive component or a simple bracket for an aerospace design, the pressures are fairly consistent: Develop a highly reliable part that can be cost effectively manufactured and do so as quickly as possible to meet accelerated time-to-delivery schedules.

That mandate, while not necessarily new, is still a quandary because it remains easier said than done.

The effort needed to work through thousands or millions of iterations can easily be beyond the reach of an engineer or team of engineers but can be well within the reach of a properly configured workstation paired with powerful Generative Design software.

Download this new white paper to learn more about the impact of emerging Generative Design tools and practices as a way to jumpstart innovation and eliminate much of the complexity surrounding iterative design workflows, as well as the hardware requirements for running these new solutions.

Download today

Latest News

Cosmetic Packaging Gets 3D Printed Upgrade

Baralan leverages Stratasys' technology to for creative packaging designs for high-end cosmetic brands, enhancing product personalization and sustainability, Stratasys reports.

GFT, NVIDIA Collaborate on AI-Based Manufacturing Apps

GFT will leverage NVIDIA AI and Omniverse tools to create visual and quality inspection applications for manufacturing. The company can...

AMD Powers Fast Supercomputer, El Capitan

El Capitan touted as the first exascale-class machine for the National Nuclear Security Administration (NNSA) stands as a computing resource...

New Program Empowering Women in 3D Printing Launches

The initiative kicks off with a dress debut and a roundtable featuring prominent female designers and creators, including FashionTech designer...

Stratasys 3D Printing Integrated in Wind Turbine Design

Gulf Wind Technology has reduced the design and fabrication cycle for wind tunnel models, according to Stratasys.

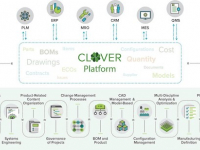

Razorleaf Updates CLOVER Digital Threat Integration Platform

Built with cloud-native technology, the updated platform offers enhanced performance and security while providing flexible deployment options—on-premise, air-gapped, cloud-based,...

All posts