June 2, 2020

3D printing provides engineers with a better way to prototype ideas and create durable end-use parts that can be ready for visual and functional evaluation in a matter of hours.

This eliminates the need for outsourcing and complex production machinery, while allowing you to create more iterations and improve product quality. Once you have finalized your design, 3D printing enables you to print durable, low-volume, and customized parts with minimal tooling costs and lead time.

This guide will help you achieve the benefits of 3D printing as quickly as possible.

Using Ultimaker fused filament fabrication (FFF) printers as examples, we will look at:

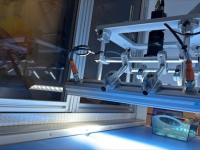

- How to set up your printer and optimize your workspace

- How to implement a 3D printing workflow

- How to make the most of 3D printing, with application ideas

This guide has been created by Ultimaker’s 3D printing experts. It also features examples from real-life engineers, so you can learn from those already using 3D printing to reduce production time and costs.

Fill out the information below to download the resource.

Latest News