3D Printed Vacuum Form Molds

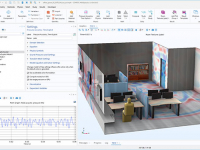

FDM (Fused Deposition Modeling) is the most common technology used for creating 3D printed molds for vacuum forming and offers many unique benefits.

September 11, 2019

FDM allows you to print in various sparse fill densities, giving the molds an inherent porosity that results in a uniform vacuum to be drawn throughout the tool. This can greatly simplify the fabrication of the tool. In addition, FDM machines are capable of printing molds in a variety of durable, heat resistant plastics that prolong the life of the mold.

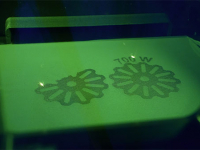

PolyJet (UV-Cured Photopolymer Jetting) is another common technology used for 3D printing molds. PolyJet-based machines build parts with fine layer resolution, and as a result, produce parts with very smooth surfaces. PolyJet vacuum form molds require little to no post processing and are great for making molds with organic and curvy surfaces.

PolyJet molds don’t share the porosity of sparse fill FDM molds, but air vents can easily be designed into critical areas of the mold prior to printing, eliminating the labor and potential inconsistency of manual drilling.

Both technologies simplify the tool fabrication, allowing engineers and designers to test multiple tooling strategies concurrently, and shortening the time to produce the first articles of a design. Other additive manufacturing technologies can be considered.

TOOL DESIGN CONSIDERATIONS

Draft - Adding draft to the vertical surfaces of a part will help when removing the mold from the newly formed plastic part. Best practice is to use a minimum draft angle of 1°-3° and a draft angle of 5° or more — this greatly helps when releasing the tool from formed parts. Undercuts can be successfully vacuum formed in special cases depending on your part geometry and material thickness.

Webbing - Geometries with deep draws and vertical walls are usually at risk for webbing during processing. More draft will help with webbing in these types of geometries. Shrink // Most plastic sheets shrink during the vacuum forming process. Shrinkage rates depend on the type of plastic used and its thickness, but usually range between 0.4% and 0.8%. You can accommodate for shrinkage in the mold design.

Sharp Corners - Use a minimum radius of curvature on tool features that is greater than the material thickness of the plastic you will be vacuum forming.

Venting - If molds are to be built in PolyJet, design vents to pull vacuum in female molds and in critical areas and recesses of male molds. Smaller diameter holes will be less noticeable on the surface of the formed parts, but size holes large enough that they are not too difficult to remove support from.

Fill out the information below to download the resource.

Latest News